Product/Technologies

Quality Assurance

디씨엠

Production range (unit : mm)

| Item | Specifications |

|---|---|

| Thickness | 0.4-1.2 |

| Sheets | 300-1,330 |

| Length | 300-5,000 |

Permissible tolerance of measurements

Thickness of original

Sheets Thickness |

Permissible thickness | |||

|---|---|---|---|---|

| Less than 630 | 630 to 1000 | 1000 to 1250 | 1250 to 1600 | |

| Less than 0.40 | ±0.04 | ±0.04 | ±0.04 | - |

| 0.40 to 0.60 | ±0.05 | ±0.05 | ±0.05 | ±0.06 |

| 0.60 to 0.85 | ±0.06 | ±0.06 | ±0.06 | ±0.06 |

| 0.85 to 1.00 | ±0.06 | ±0.06 | ±0.07 | ±0.08 |

| 11.00 to 1.25 | ±0.07 | ±0.07 | ±0.08 | ±0.09 |

Product width (units: mm)

Sheets Thickness |

Permissible tolerance | |

|---|---|---|

| Less than 1250 | More than 1250 | |

| Mill edge | 0, +7 | 0, +10 |

| Slitting edge | ±0.5 | |

Product length (units: mm)

| Length | Permissible tolerance |

|---|---|

| 300≤L≤3500 | ±0.5mm |

| 3500<L≤5000 | ±1.0mm |

Original (base metal) product specifications

| Section | POSCO | KS/JIS | ASTM | Mechanical properties | ||

|---|---|---|---|---|---|---|

| YP | TS | EL | ||||

| EGI | EGSC | SECC | AS591-CQ | - | ≥270 | ≥37 |

| GI | CGCC | SGCC | A526 | - | ≥270 | - |

| CR | CSP1 | SPCC | A1008CS | ~392 | ≥270 | 34~ |

Packing method

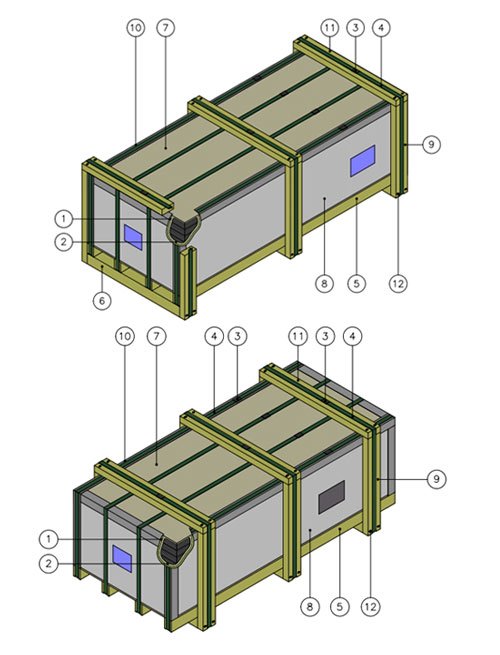

A. Sheet

| No. | Material | Specification |

|---|---|---|

| 1 | Water Proof Paper | 450 |

| 2 | Rust Proof Paper | 200 |

| 3 | Clip | 0.7x30x45(GI) |

| 4 | Steel Band or P.P band | 1Tx25w(PP) |

| 5 | Wood Skid | 50Tx70W |

| 6 | Wood Skid | 70Tx90W |

| 7 | Fly Wood | 10T |

| 8 | Protective Steel Sheet | 0.6T |

| 9 | Wood Skid | 40x80W |

| 10 | Coner Angle | 0.6Tx60Wx60W |

| 11 | Wood Skid | 40Tx80W |

| 12 | Nail | 70L |

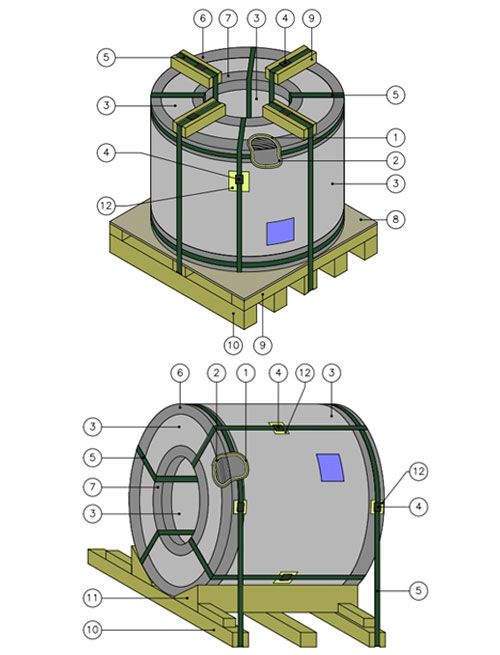

B. Coil

| No. | Material | Specification |

|---|---|---|

| 1 | Water Proof Paper | 450 |

| 2 | Rust Proof Paper | 200 |

| 3 | Protective Steel Sheet | 0.6T(EGI, GI) |

| 4 | Clip | 0.7x30x45(GI) |

| 5 | Steel Band or P.P band | 1Tx25W |

| 6 | Outside Ring | 0.8Tx55Wx95W(GI) |

| 7 | Inside Ring | 1.7Tx55Wx45W(GI) |

| 8 | Fly Wood | 10T |

| 9 | Wood Skid | 50Tx70W |

| 10 | Wood Skid | 70Tx90W |

| 11 | Angle Wood Skid | 70Tx120W |

| 12 | Seal Pad | 70L |